Projects

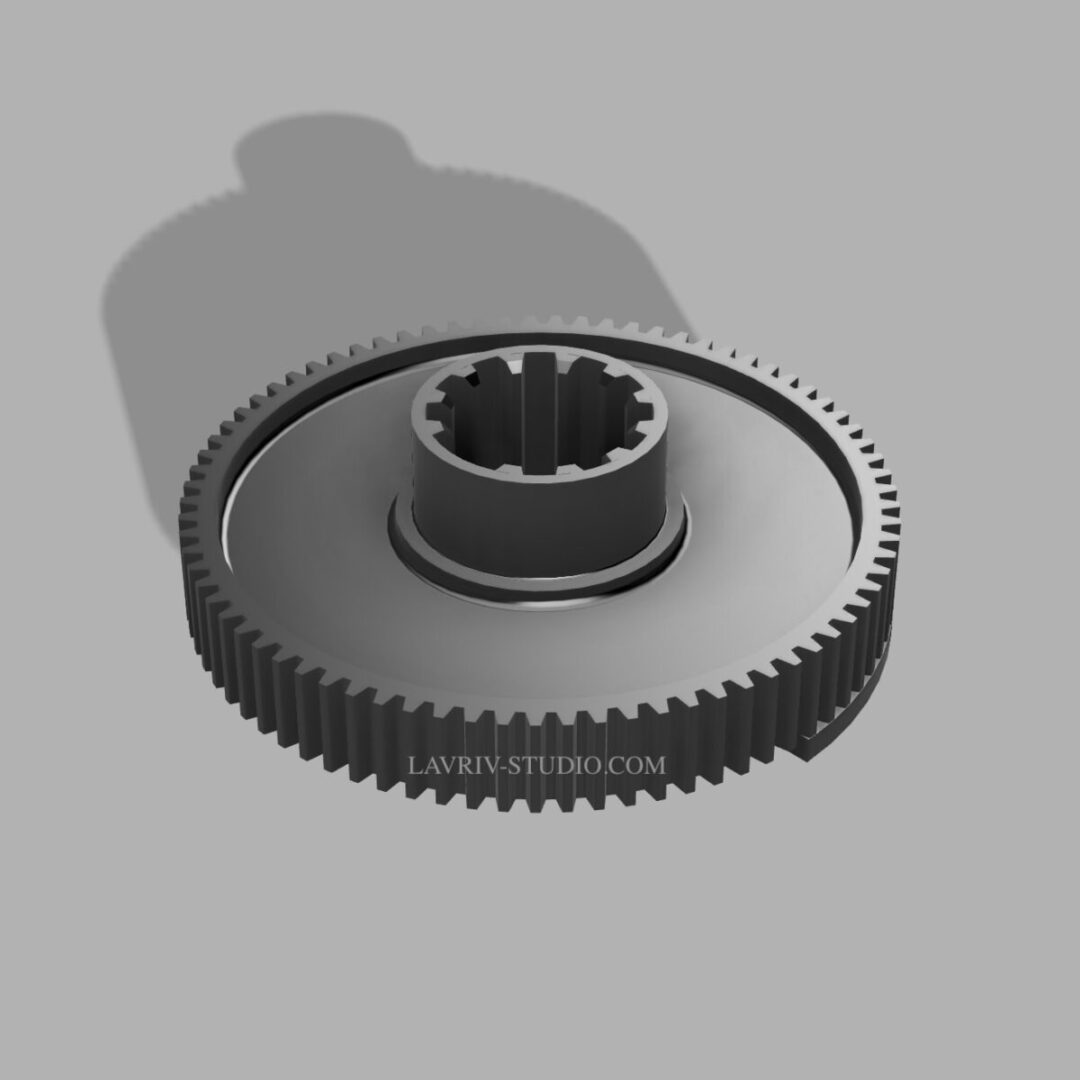

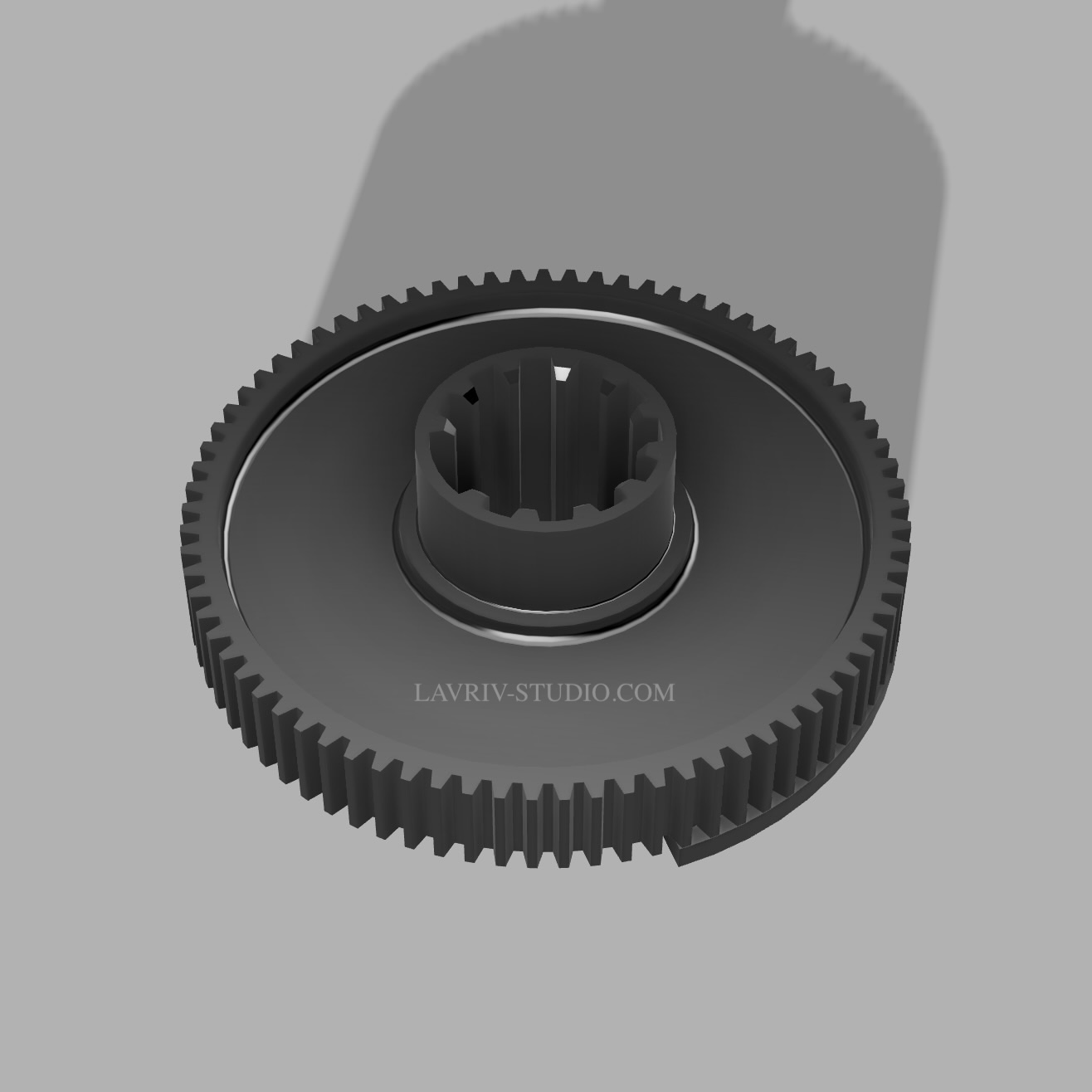

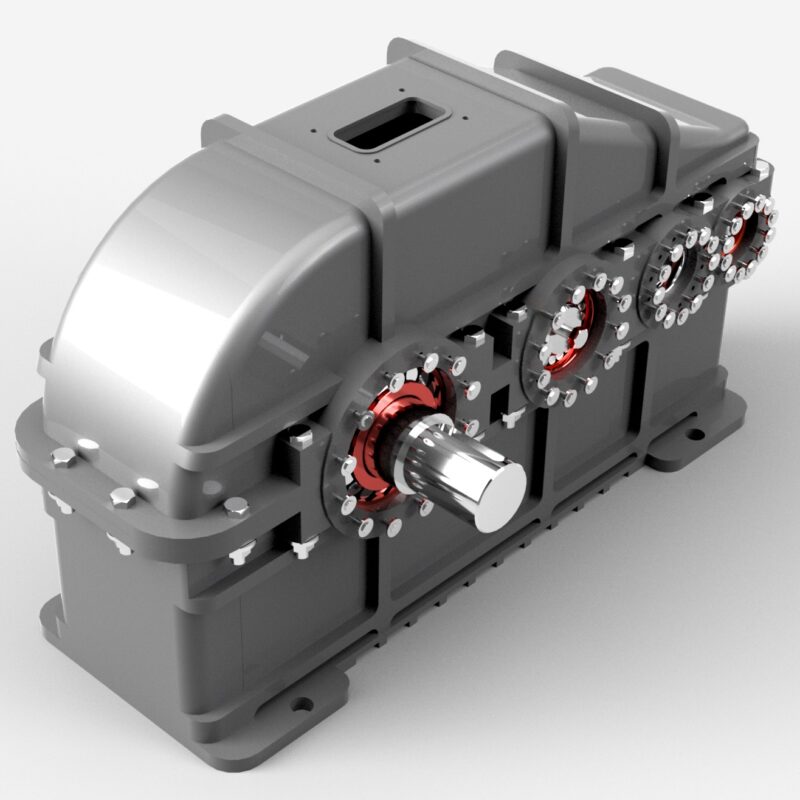

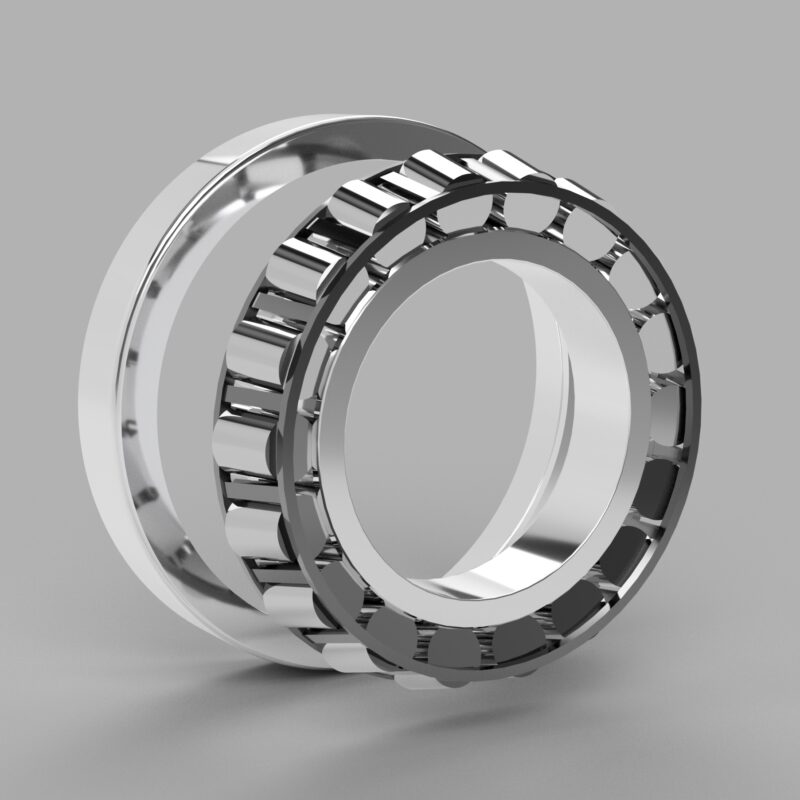

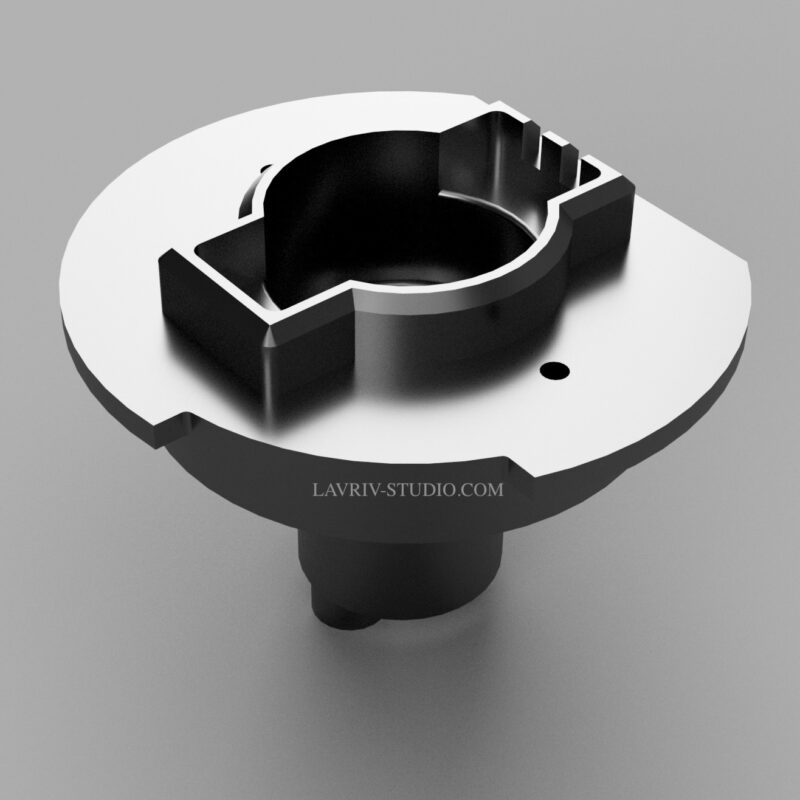

Precision Gear Design

Lavriv Studio — Engineering Motion with Accuracy

Designing gears is one of the most demanding areas of mechanical CAD work — where geometry, tolerance, and kinematics must align perfectly.

At Lavriv Studio, we develop custom gear systems for robotics, mechanical drives, and motion prototypes, using the full power of parametric 3D modeling in Fusion 360.

Design & Development Workflow

1. Geometric Foundation

The process starts with defining involute tooth geometry, module, pressure angle, and pitch diameter.

Each gear is modeled parametrically, allowing dynamic adjustment of tooth count, ratio, and center distance — without rebuilding the entire model.

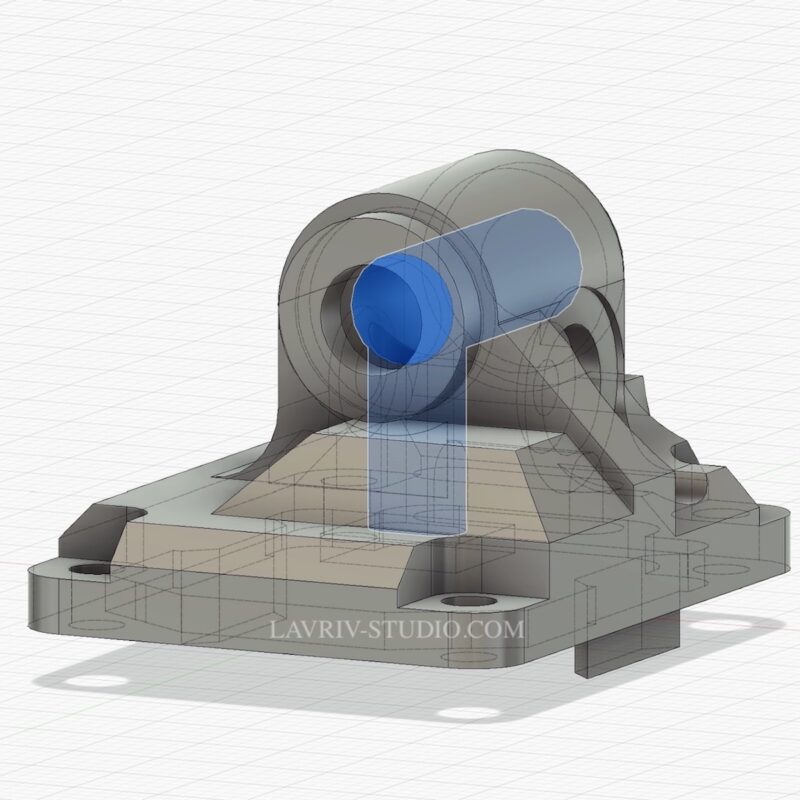

2. Parametric 3D Modeling

Through Fusion 360’s Gear Generator and custom scripts, we build accurate 3D models for spur, bevel, and helical gears.

Constraints and relationships are used to ensure precise meshing and rotational symmetry.

3. Motion & Assembly Simulation

Using Joint and Motion Study, we test the gear pair or gear train under real conditions.

This includes backlash control, rotation smoothness, and torque transfer accuracy.

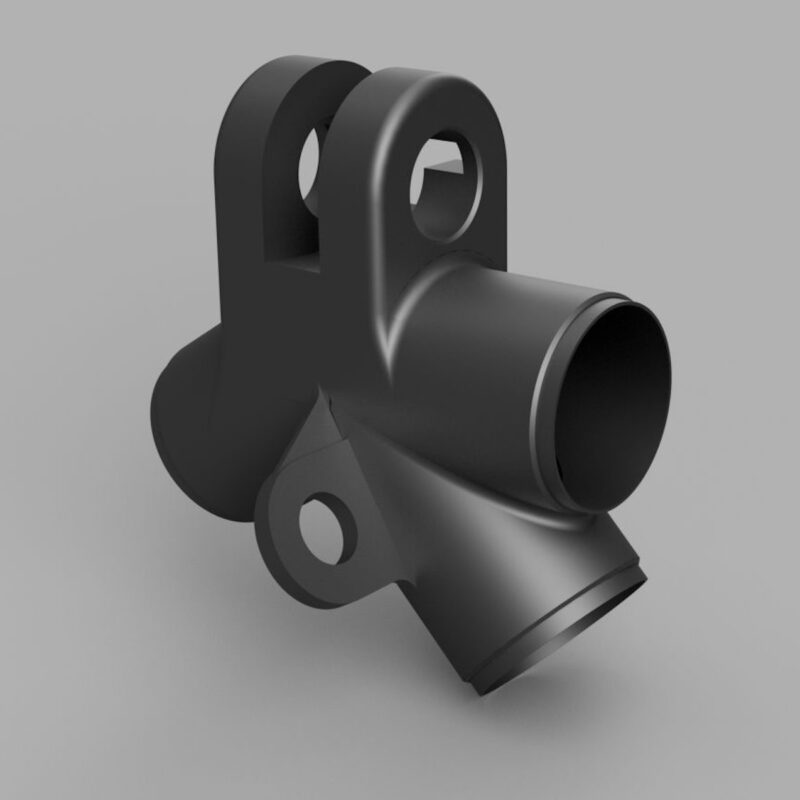

4. Optimization for Manufacturing

Final geometries are refined for CNC machining or high-resolution 3D printing.

We control tolerances, chamfers, and reliefs to ensure silent operation and long service life.

Result

The outcome is a precision-engineered gear system — optimized for performance, strength, and manufacturability.

Each project reflects our philosophy: motion starts with perfect geometry.

Lavriv Studio

We turn mechanical precision into seamless motion.

| Designer | LAVRIV STUDIO |

|---|---|

| Software | Fusion 360 |

| Website | https://lavriv-studio.com |