Projects

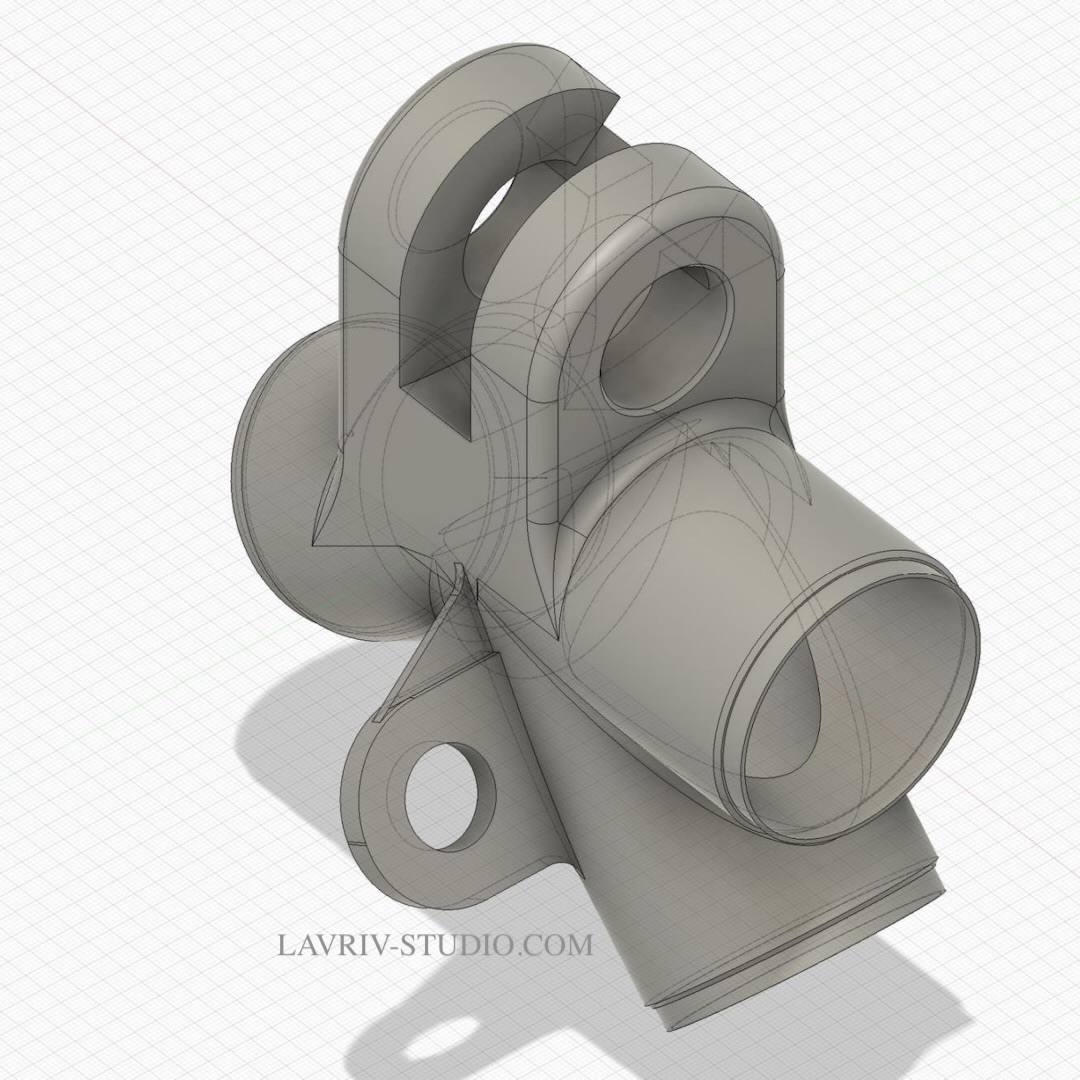

Precision Bracket Design

Lavriv Studio — Engineering Accuracy in Every Detail

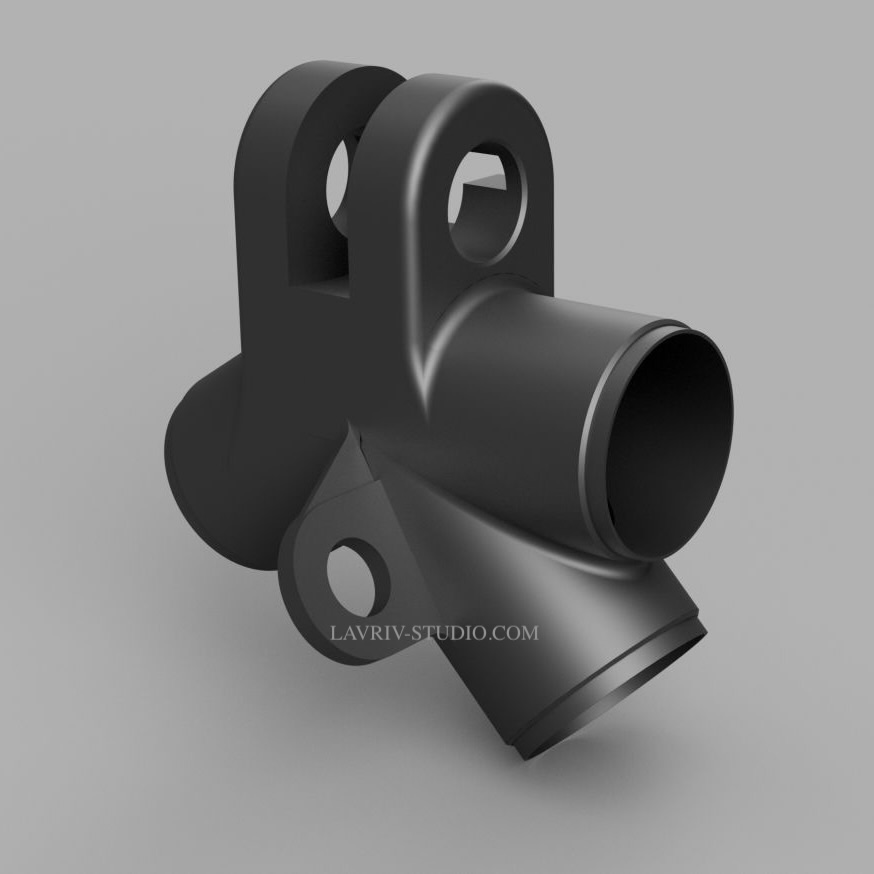

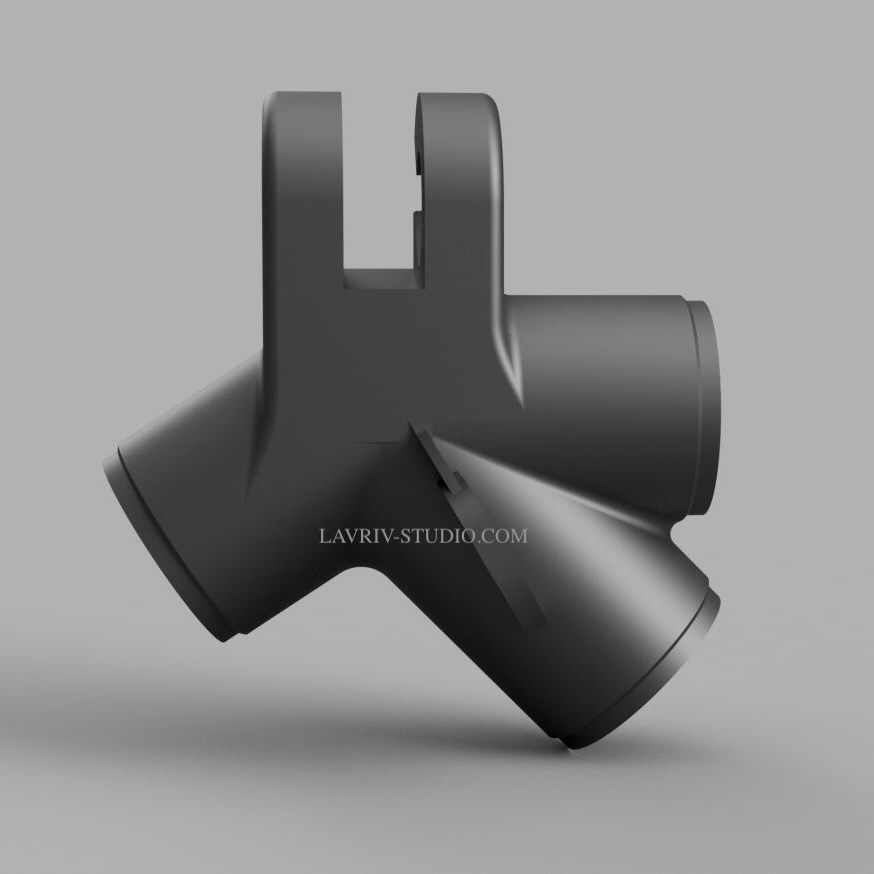

In this project, our goal was to design a structural bracket capable of maintaining precise alignment and mechanical strength under complex loads.

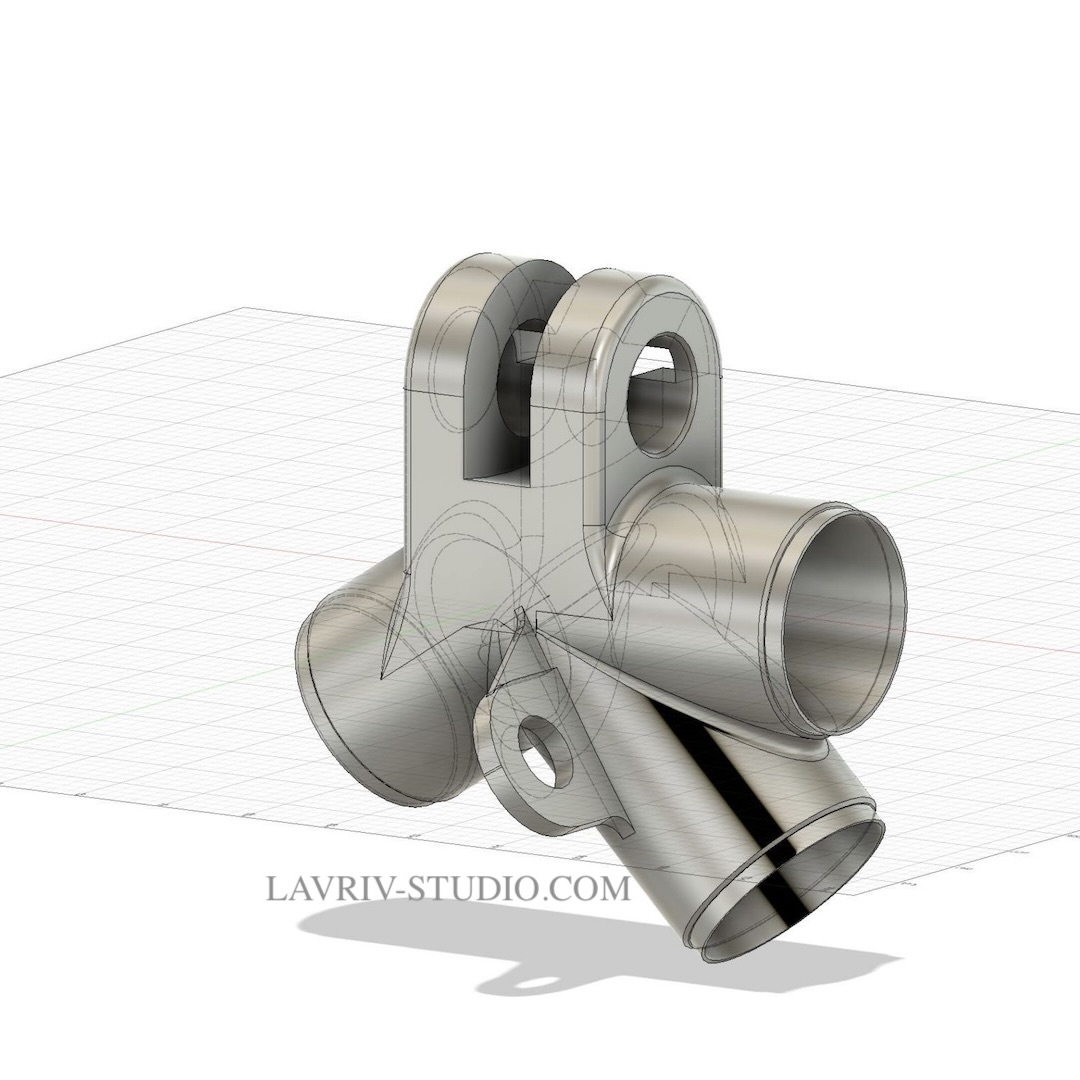

The entire workflow — from initial sketching to the final rendered model — was executed in Fusion 360, using parametric and constraint-driven modeling techniques.

Design & Development Process

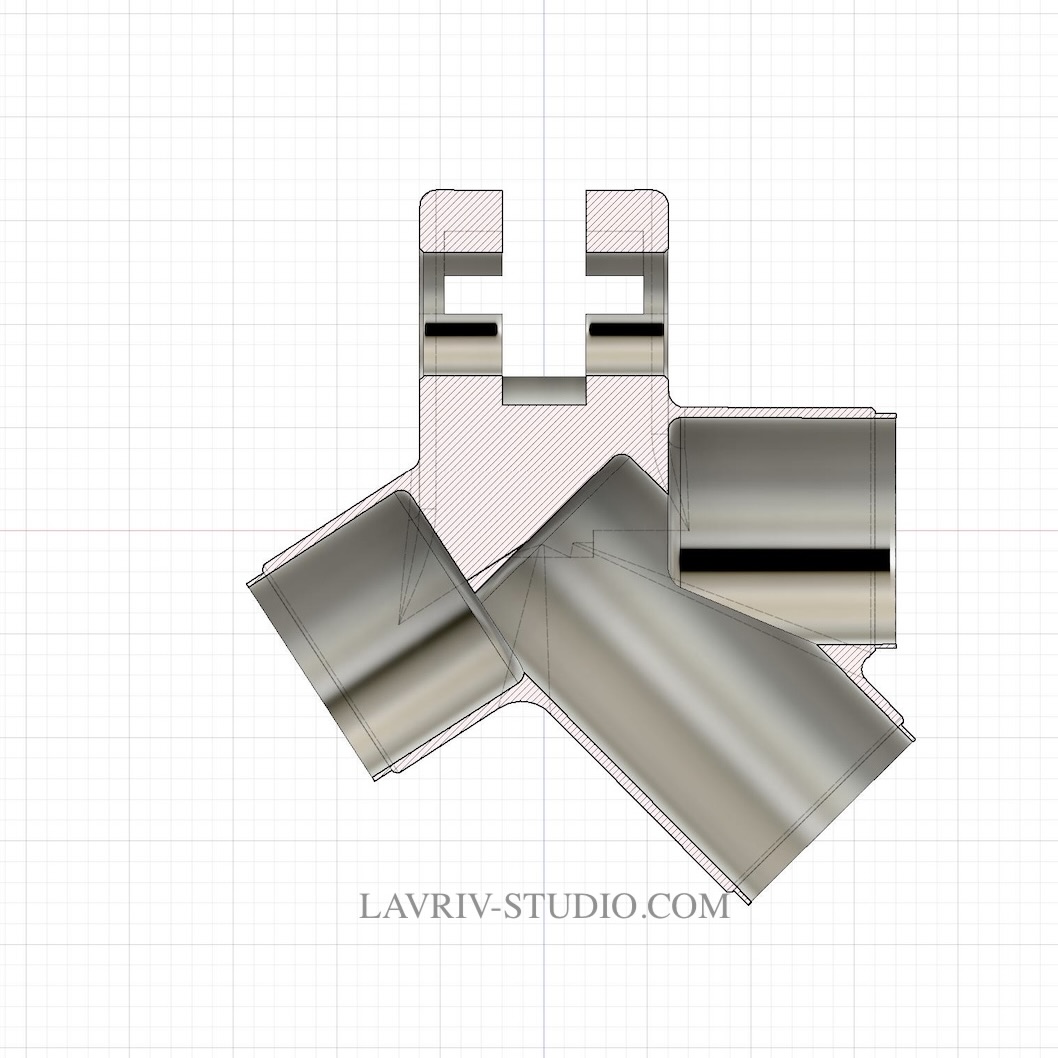

1. 2D Drafting and Geometric Definition

The project began with the creation of a detailed technical drawing defining key geometries, angles, and tolerances.

All dimensional dependencies were parameterized to ensure quick adaptation for future iterations or load-specific redesigns.

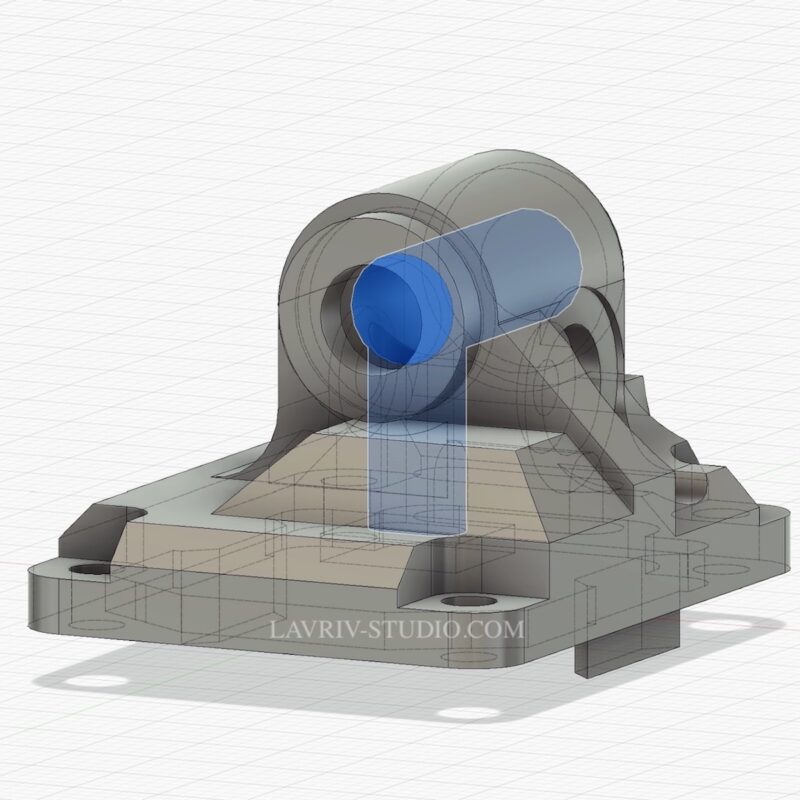

2. 3D Parametric Modeling

Using precise reference planes and constraints, the bracket was modeled to achieve both rigidity and manufacturability.

Smooth transitions and reinforced fillets were applied to minimize stress concentration in load-bearing areas.

3. Functional Integration

The design includes multiple cylindrical joints and mount interfaces, providing compatibility with mechanical linkages and motion systems.

Each angle and offset was optimized for proper alignment and simplified assembly.

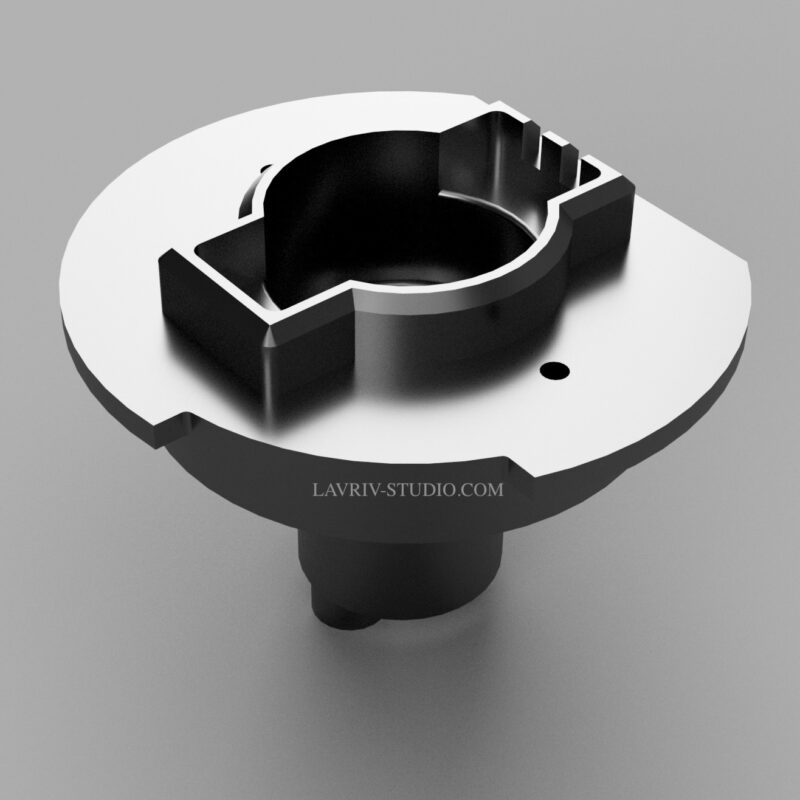

4. Visualization & Rendering

The final model was rendered in Fusion 360 to visualize surface geometry, curvature flow, and light behavior — ensuring both technical accuracy and aesthetic balance before production.

Outcome

The result is a lightweight yet durable CAD model ready for manufacturing or simulation.

This bracket design demonstrates our commitment to combining precise geometry, mechanical functionality, and visual clarity — the essential qualities behind every Lavriv Studio project.

| Designer | LAVRIV STUDIO |

|---|---|

| Software | Fusion 360 |

| Website | https://lavriv-studio.com |