Projects

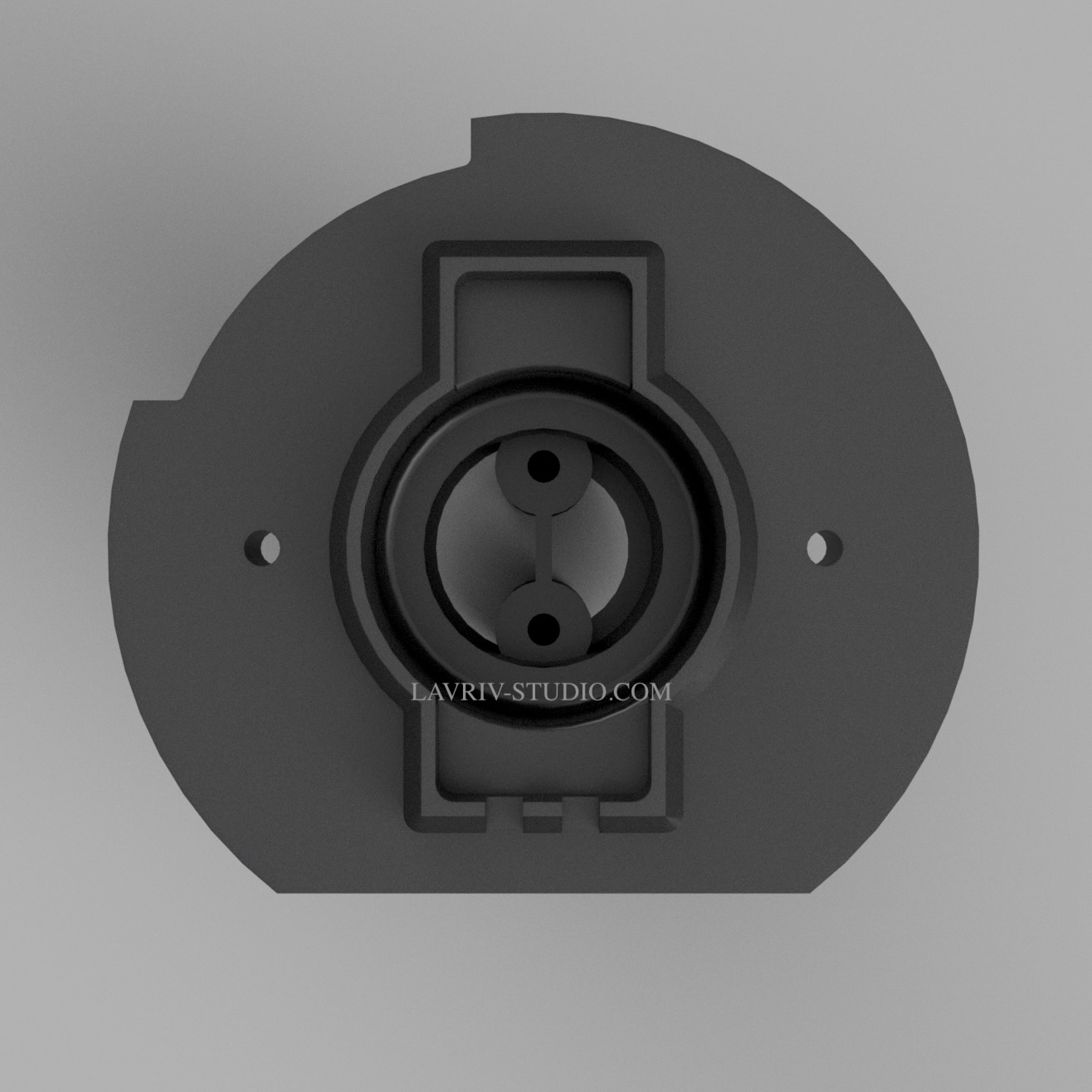

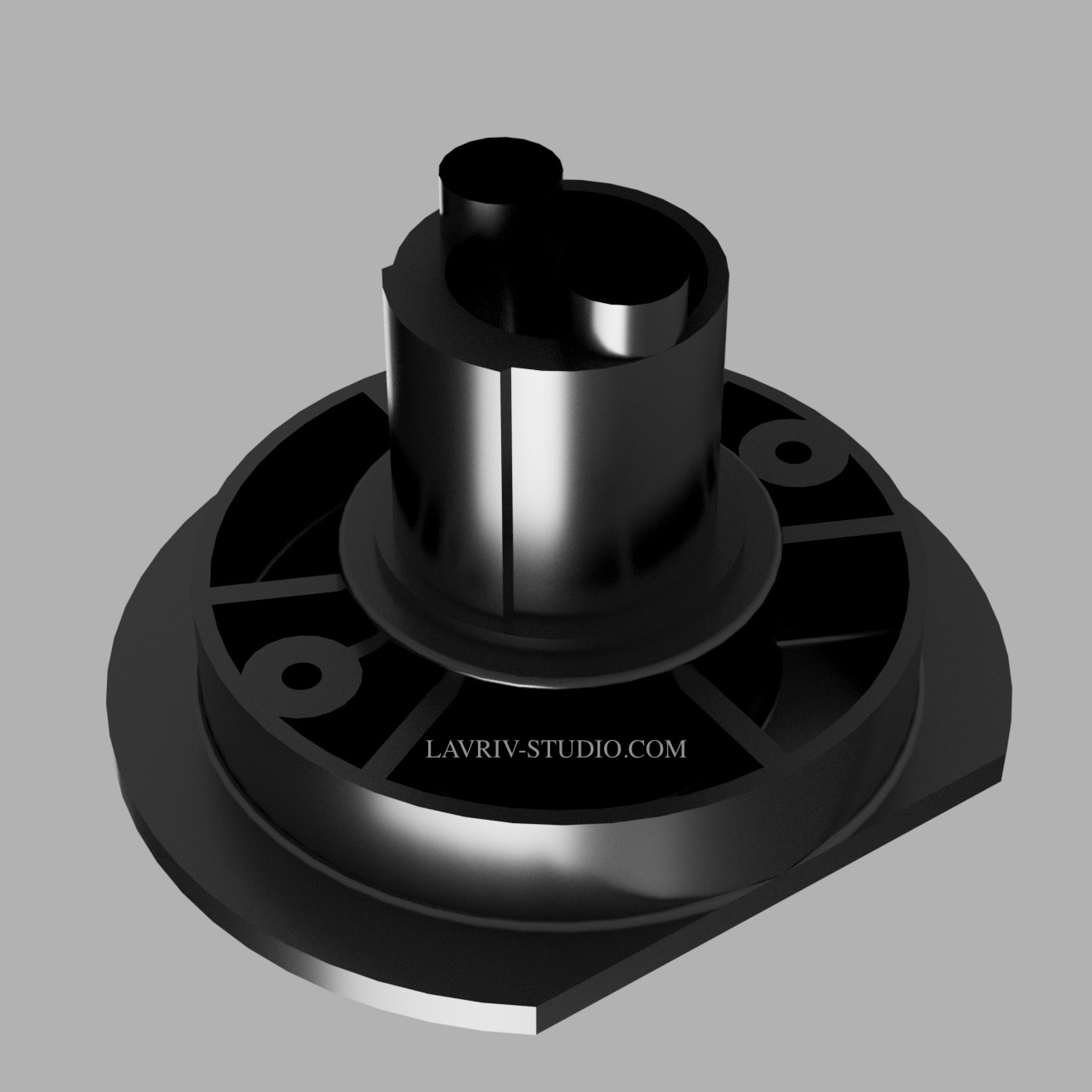

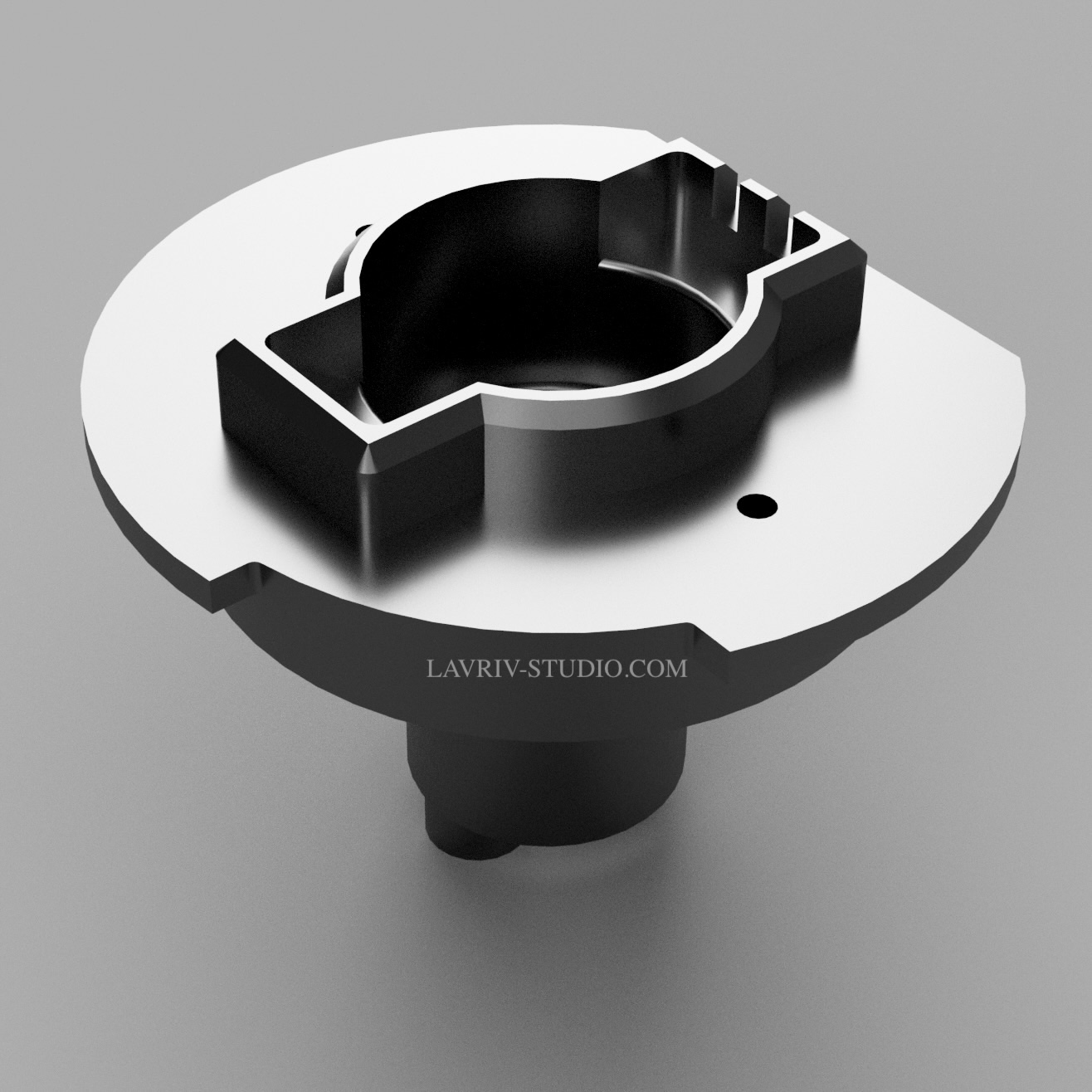

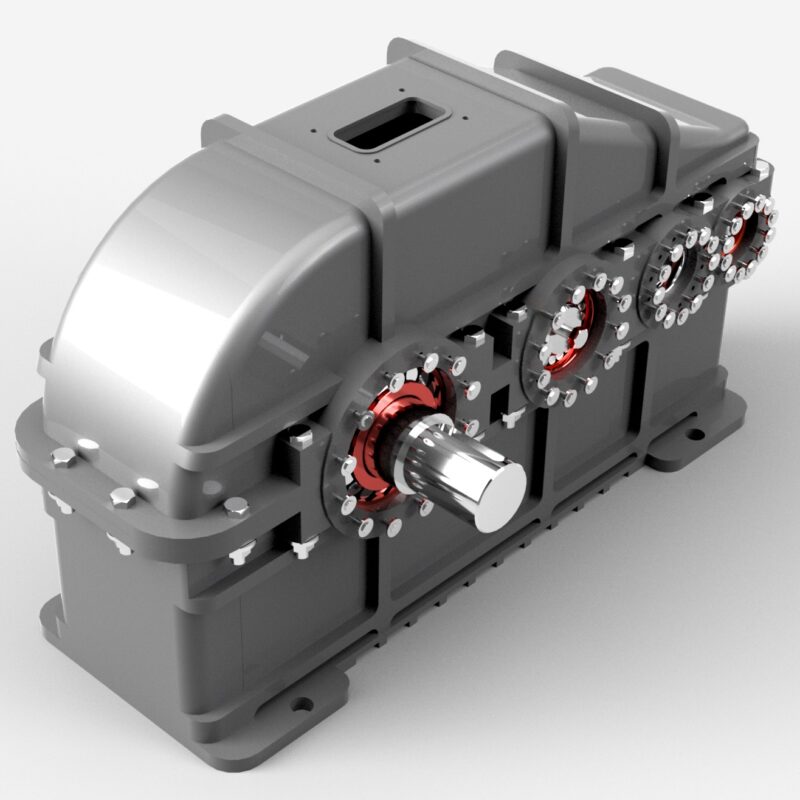

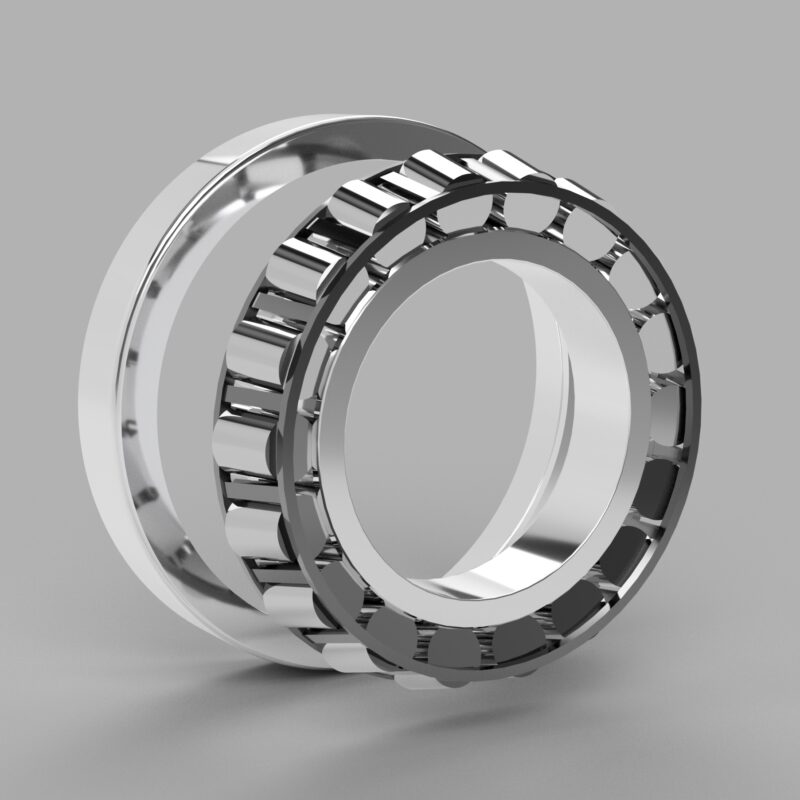

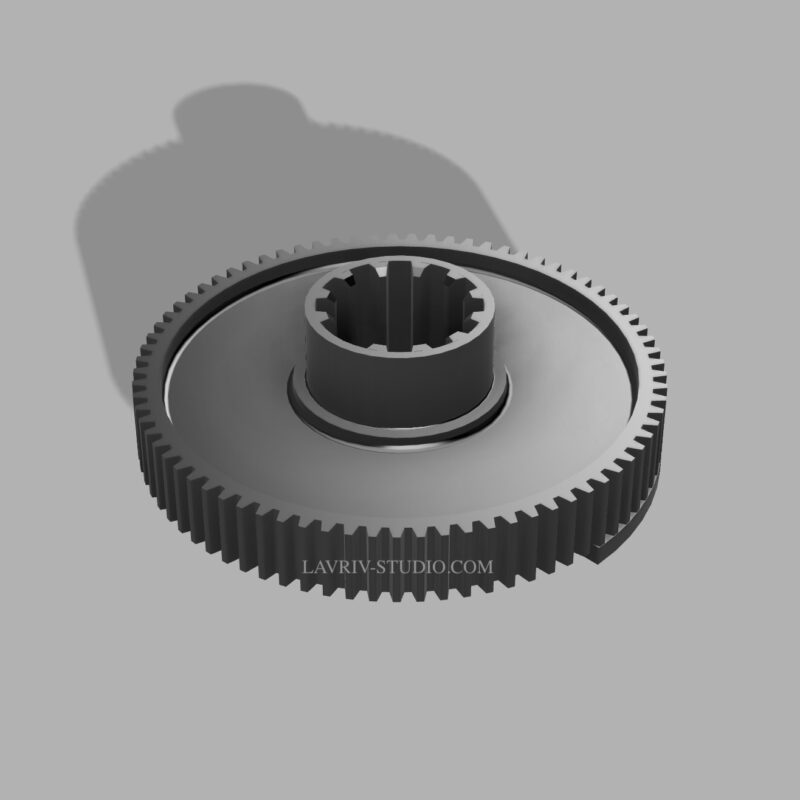

CAD Design of Mechanical Spare Parts

Lavriv Studio — From Idea to Precise Digital Geometry

At Lavriv Studio, we specialize in the 3D design and reverse engineering of mechanical components — from small replacement parts to complex assemblies.

Our focus is on accuracy, manufacturability, and compatibility, ensuring every model can move seamlessly from the digital stage to real-world production.

Design Process

1. Reverse Engineering & Measurement

The workflow begins with detailed geometry analysis of the original component — using measurements, sketches, or 3D scans.

This step allows us to recreate parts that are no longer in production, or to modify existing ones for performance upgrades.

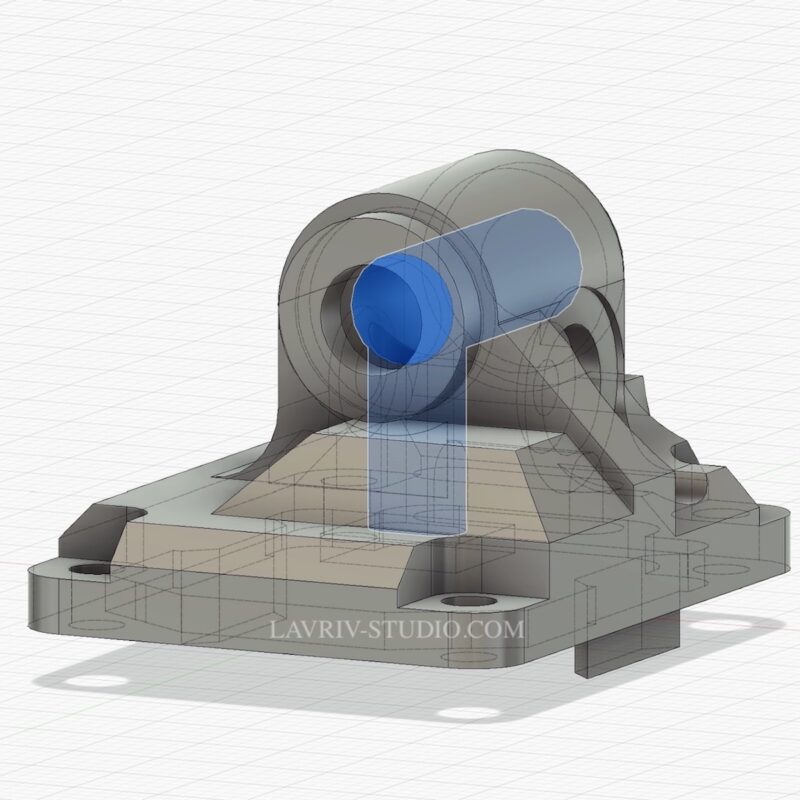

2. Parametric Modeling in Fusion 360

Each part is modeled using parametric constraints and reference geometry, ensuring perfect dimensional relationships.

Such an approach allows for instant adjustments — for example, when adapting a part for new tolerances or materials.

3. Optimization & Structural Analysis

We apply Stress Simulation and Generative Design to reduce weight while maintaining structural integrity.

This guarantees durability and efficiency even under dynamic mechanical loads.

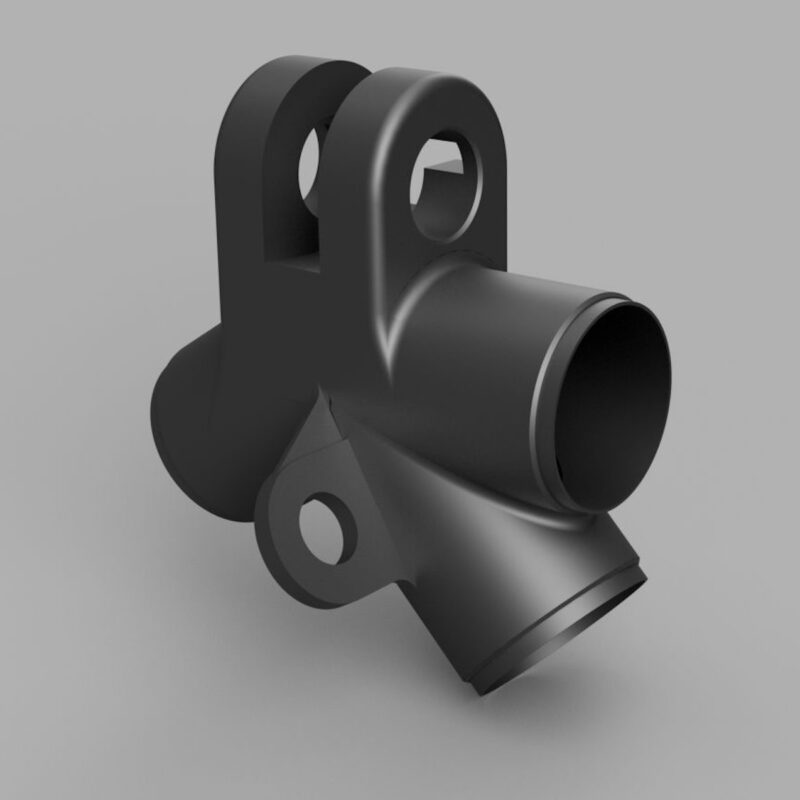

4. Preparing for Manufacturing

All models are finalized for CNC machining or 3D printing, with detailed control of fits, tolerances, and surface finishes.

Export formats (STEP, STL, DXF) are tailored to match the requirements of the chosen manufacturing process.

Result

The result is a fully functional, production-ready 3D model that restores or enhances the original component’s performance.

Each project demonstrates our principle: precision engineering is not just design — it’s a digital foundation for real-world reliability.

Lavriv Studio

Transforming mechanical ideas into exact, manufacturable CAD models.

| Designer | LAVRIV STUDIO |

|---|---|

| Software | Fusion 360 |

| Website | https://lavriv-studio.com |