Projects

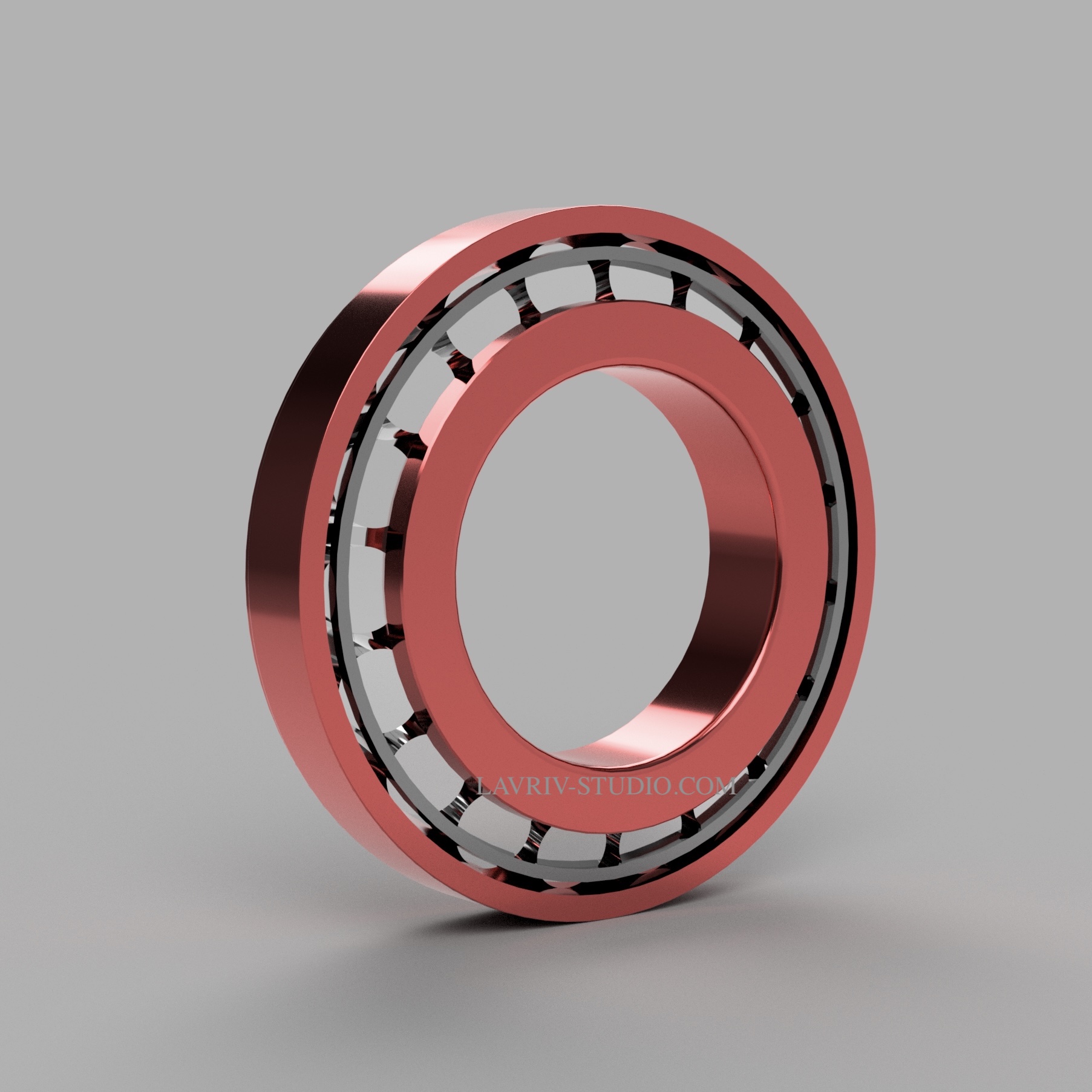

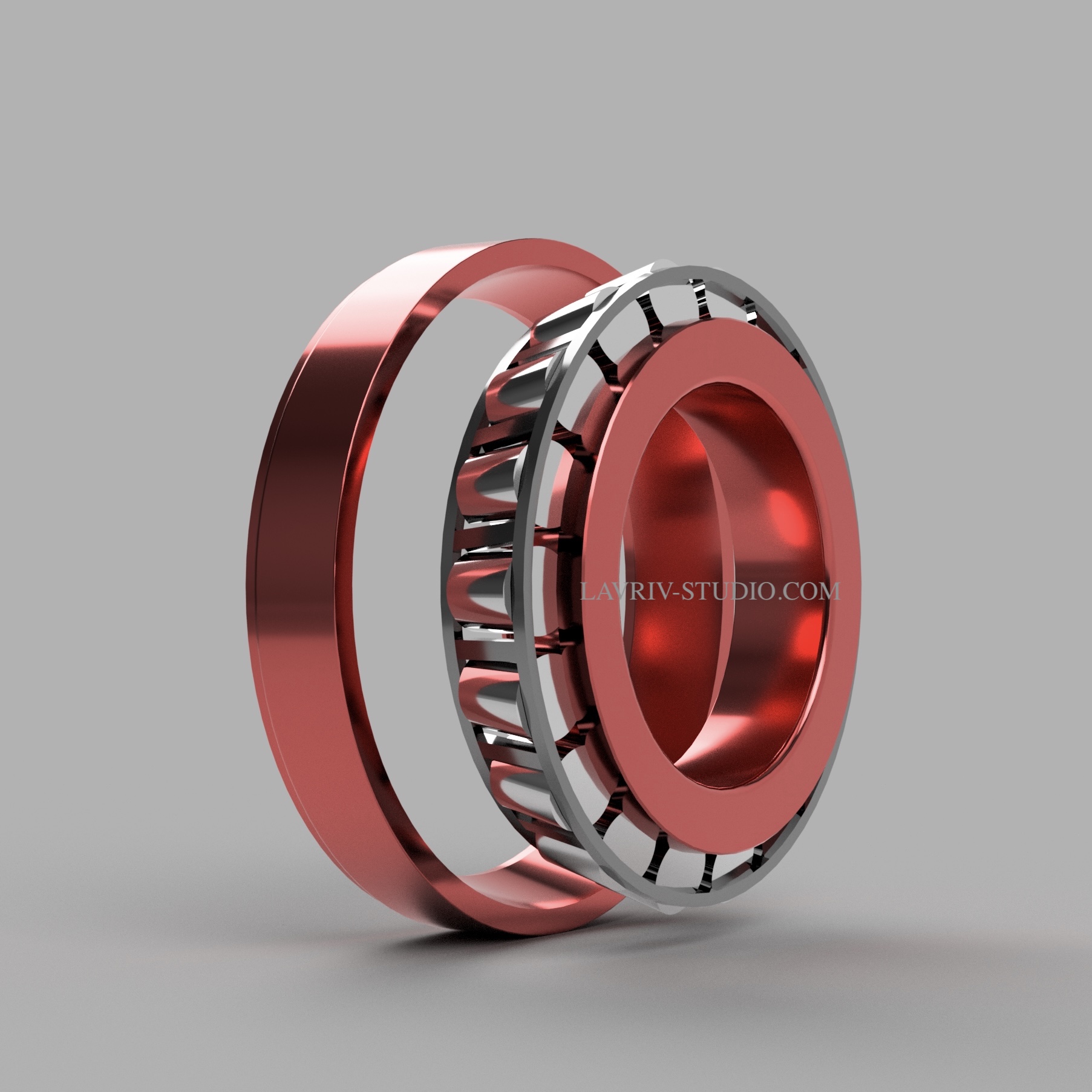

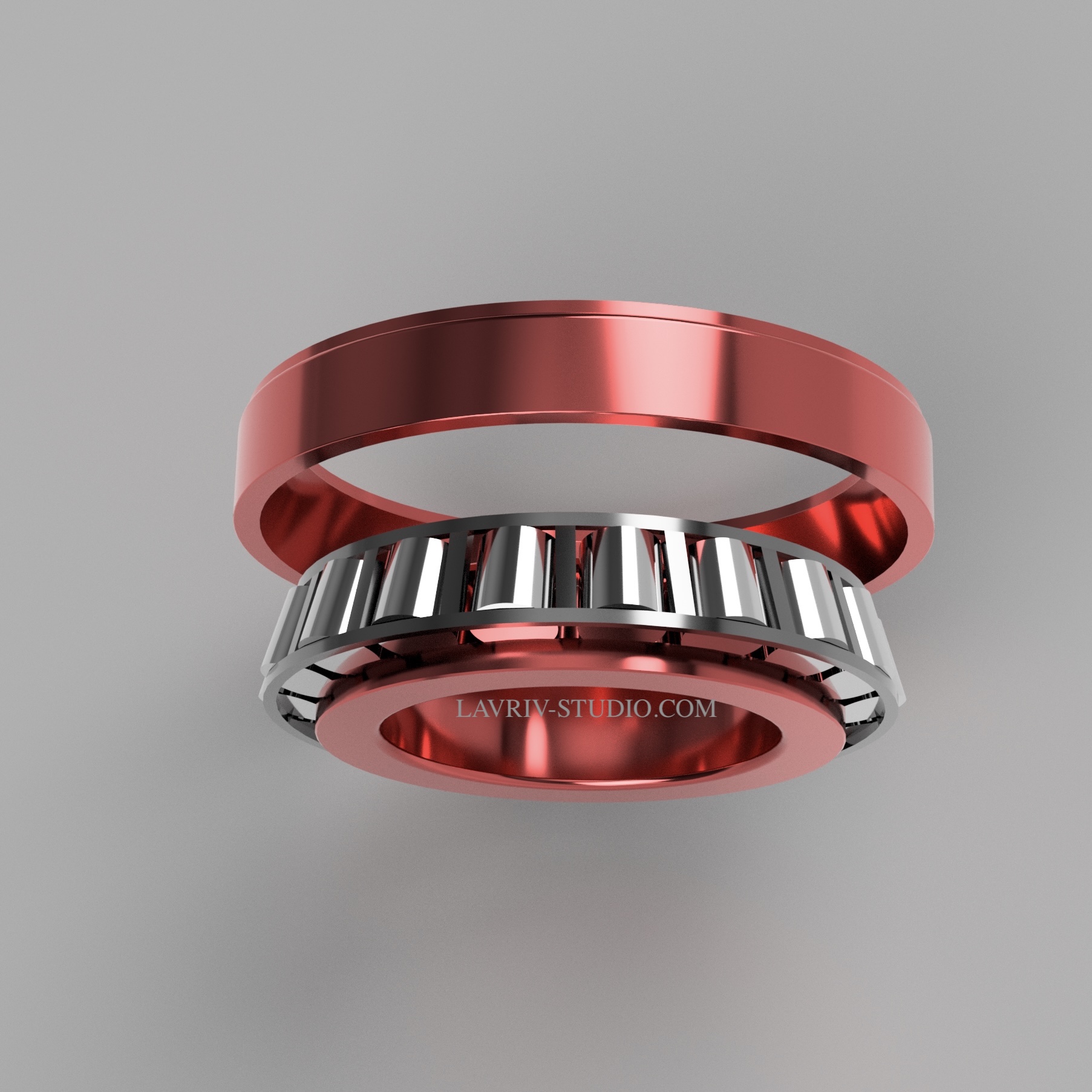

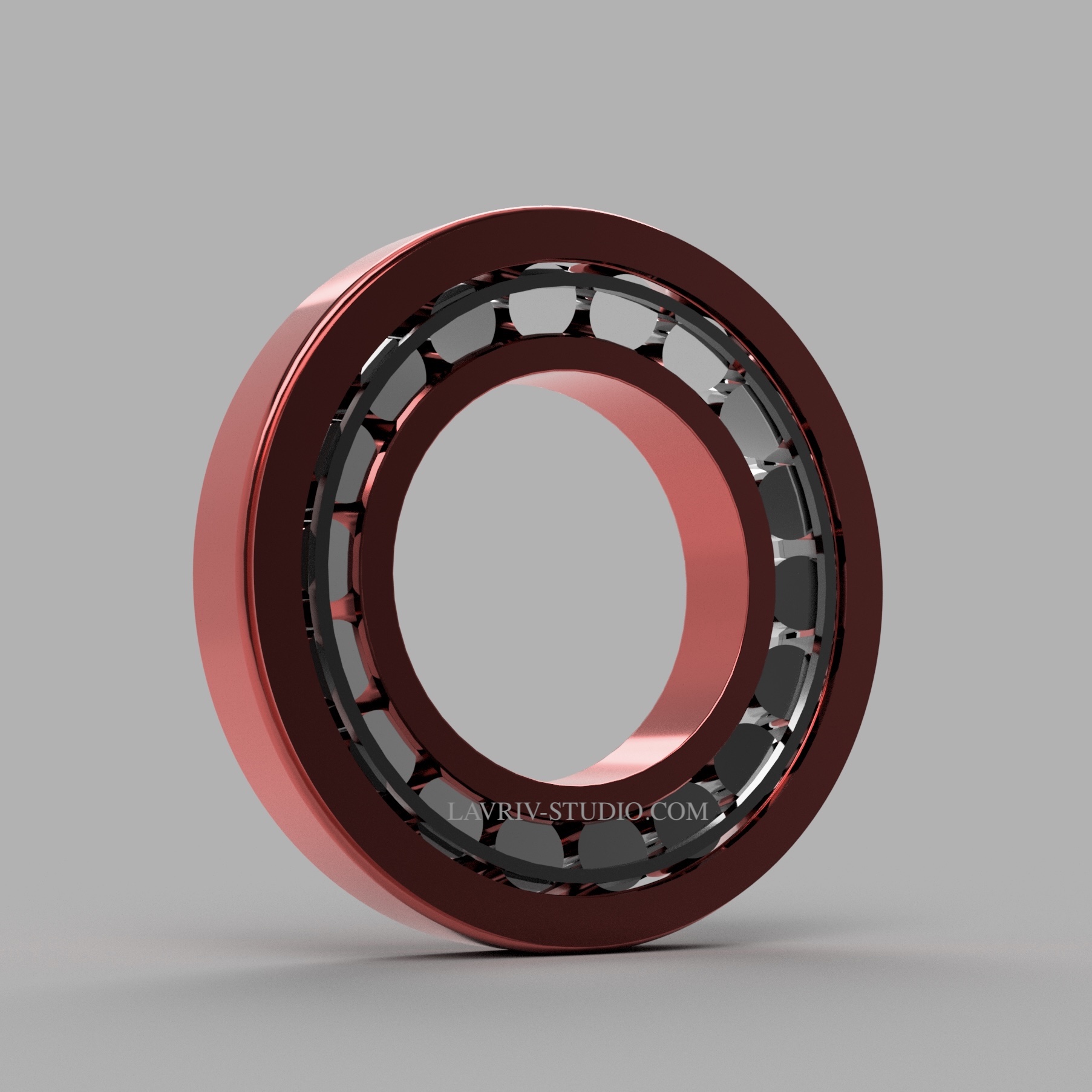

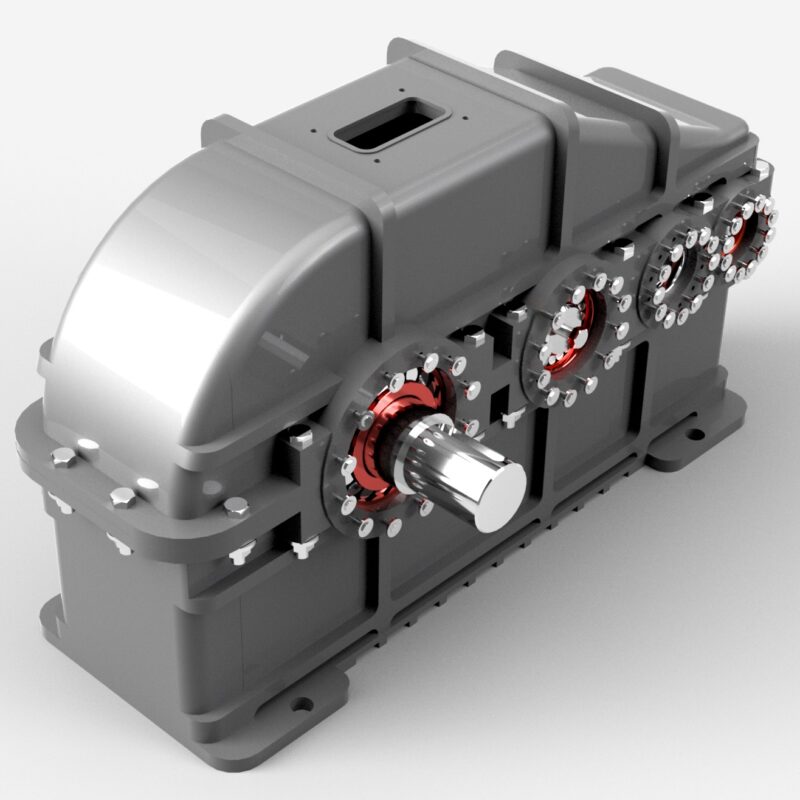

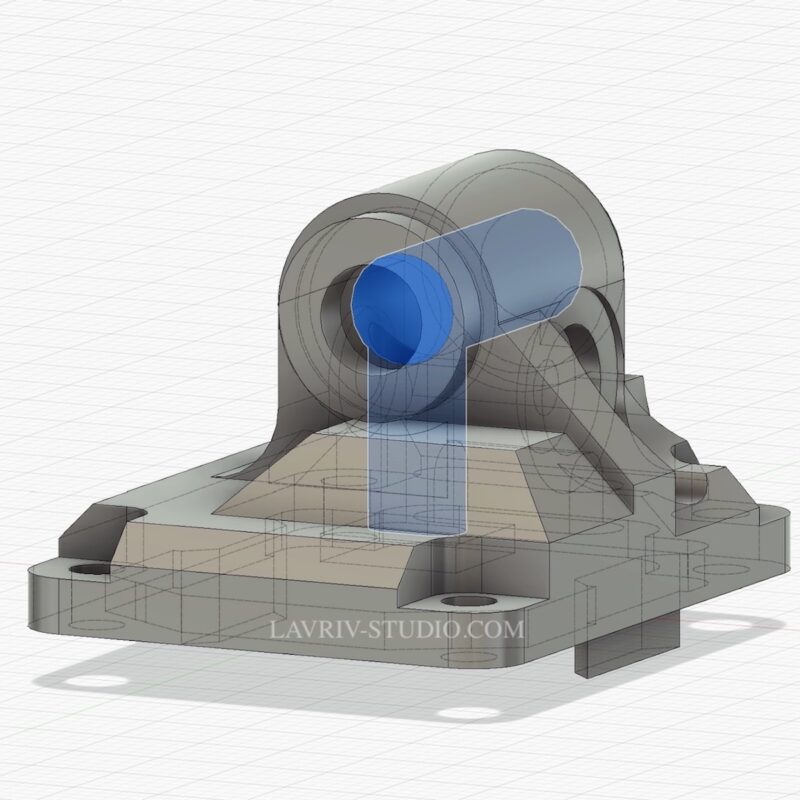

30220 Bearings for Reduction Gearbox

Lavriv Studio — Precision Components for Precision Systems

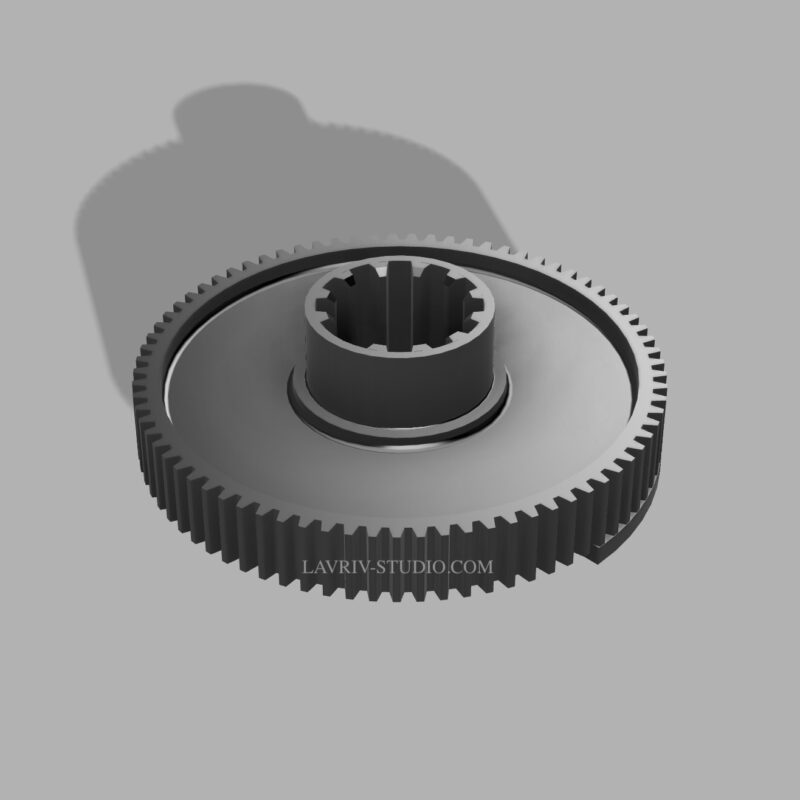

In the development of the Reduction Gearbox project, a key stage was creating a highly accurate CAD model of the 30220 tapered roller bearings.

These bearings are responsible for transferring radial and axial loads between the gearbox shafts while maintaining minimal friction and precise alignment.

At Lavriv Studio, every detail — from rolling elements to housing fits — is modeled with micrometer-level precision to ensure perfect mechanical integration.

Design & Modeling Workflow

1. Geometric Reference & Standards

The modeling began with studying ISO and SKF data sheets for the 30220 series.

Dimensional parameters such as inner/outer diameters, width, and contact angle were defined according to DIN 720 and ISO 355 standards.

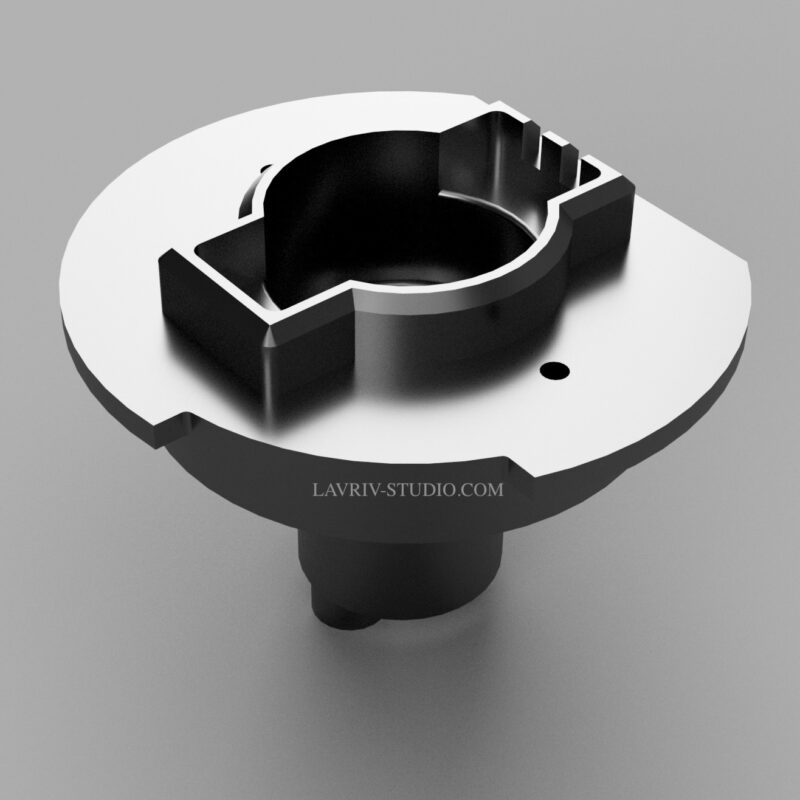

2. Parametric 3D Modeling

The bearing was built in Fusion 360 and SolidWorks, using parametric constraints for rings, rollers, and cage geometry.

This approach allows easy adaptation to other bearing types or sizes without rebuilding the model.

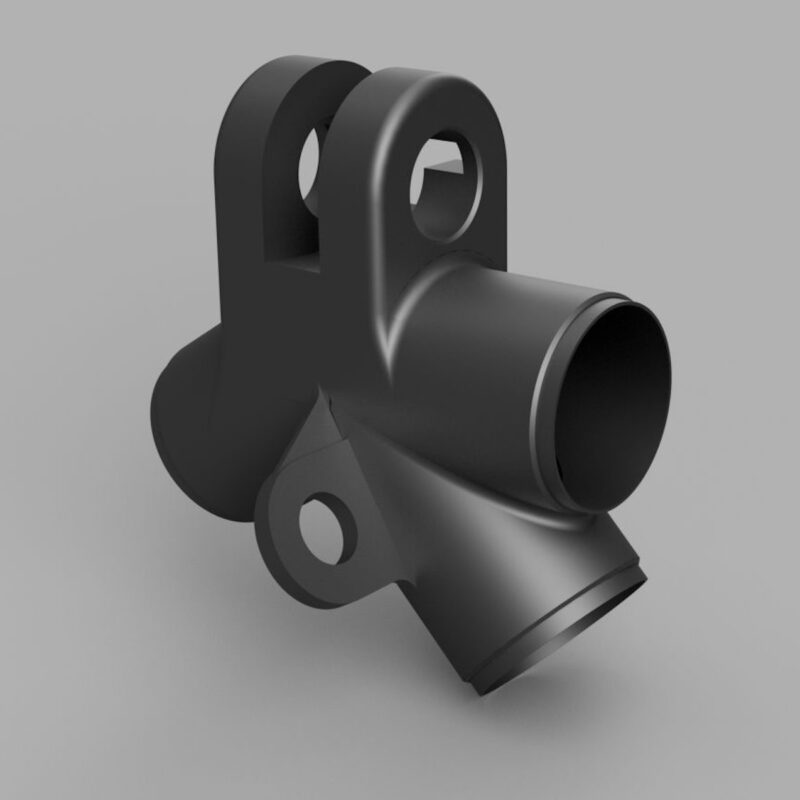

3. Assembly Integration

The model was precisely aligned within the Reduction Gearbox assembly.

The As-Built Joint and Motion Study tools were used to simulate shaft rotation, ensuring correct contact surfaces and load transfer.

4. Detailing & Visualization

Surface fillets, chamfers, and clearances were included for accurate rendering and technical documentation.

The final model was exported in STEP and STL formats for use in manufacturing drawings and mechanical analysis.

Result

The 30220 bearing model became an integral part of the gearbox kinematic system, ensuring proper load distribution and long-term reliability.

This stage demonstrates the Lavriv Studio approach — where even the smallest component is designed with the same precision as the entire mechanism.

| Designer | LAVRIV STUDIO |

|---|---|

| Software |

SolidWorks, Fusion 360 |

| Website | https://lavriv-studio.com |